| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

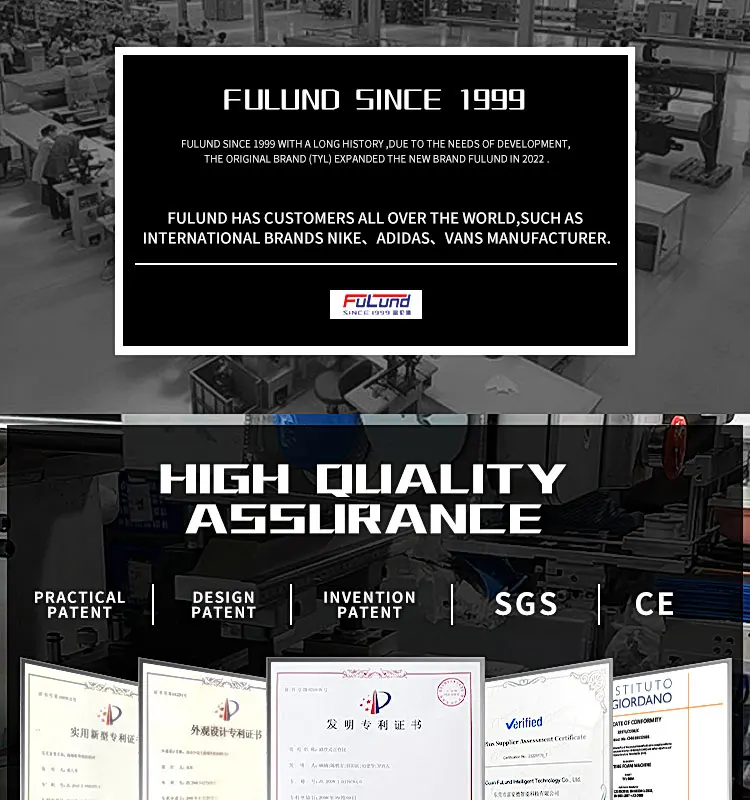

Brand Name : Fulund

Model Number : FLD-18b

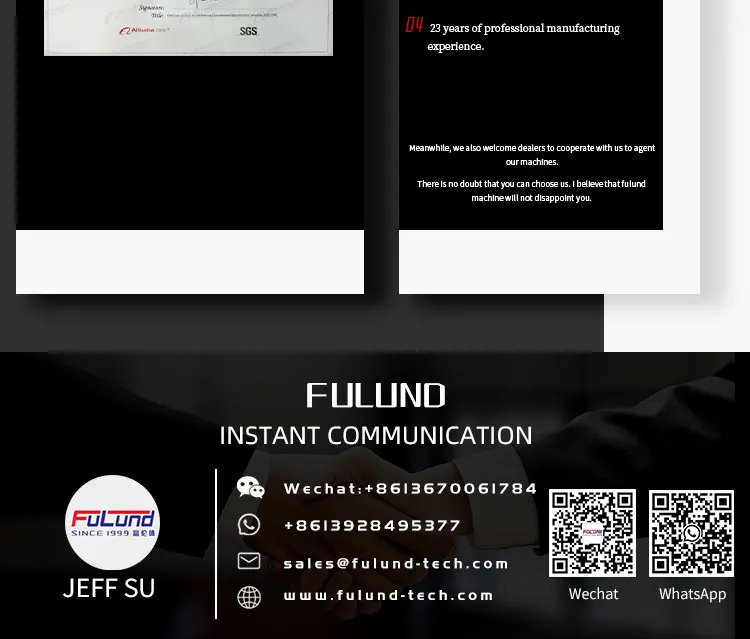

Certification : CE

Place of Origin : CHINA

MOQ : 1

Price : USD

Payment Terms : T/T, Western Union, MoneyGram

Supply Ability : 100PCS/MONTH

Delivery Time : 7days

Packaging Details : WOODEN CASE

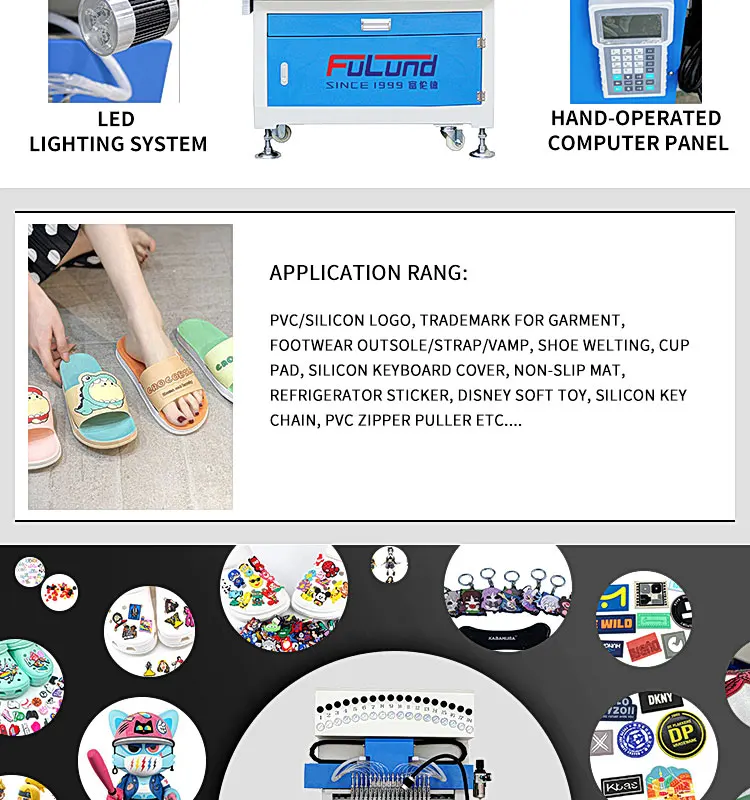

NAME : Dispensing Machine

Automatic grade : Full Automatic

Dimension(L*W*H) : 900*950*1630mm

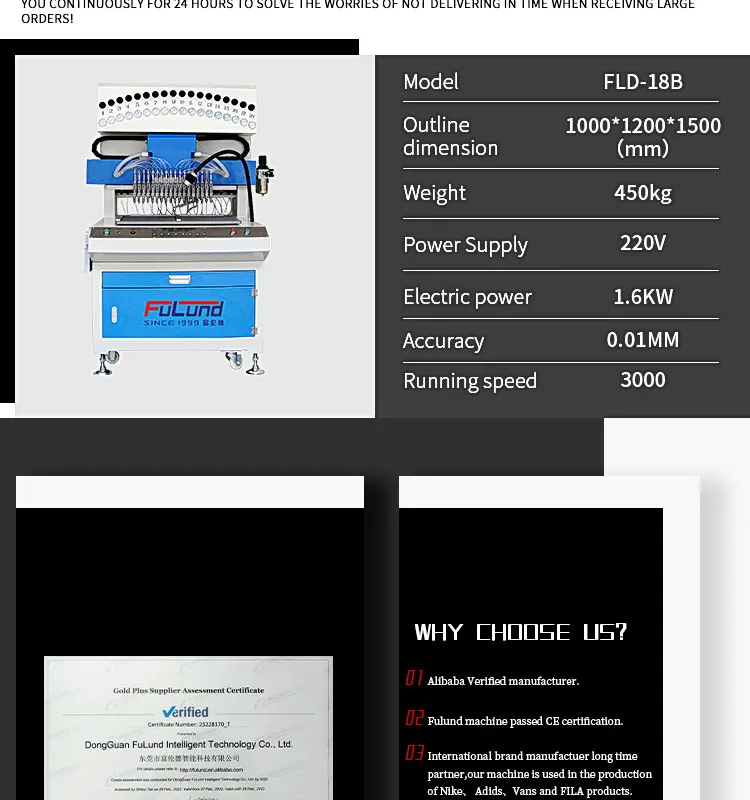

Product Name : 18 color drop molding machine

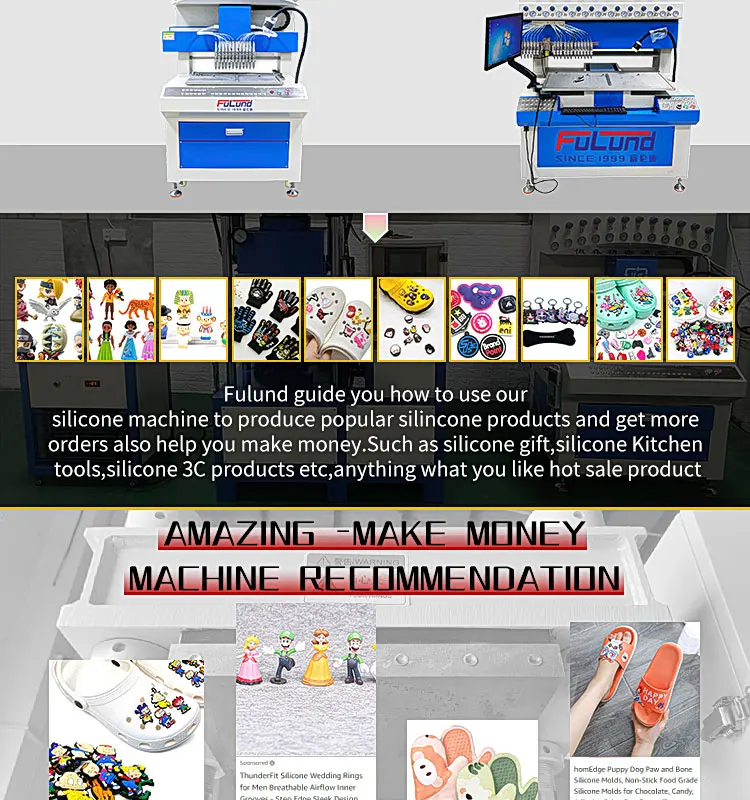

Application : Production of PVC and silica gel products

Mould Life : 100k- 500k Shots

Voltage : 220V

Weight : 330

Power (kW) : 1.6

Surface treatment : Texture

Keyword : Plastic Injection Mold Molding Services

Shaping Mode : Plastic Injection Mould

Cavity : Single Cavity\ Multiple Cavity

Technical parameters:

| Model No. | FLD-18b |

| Machine Size | 900*950*1630mm |

| Weight | 330KG |

| Electric heating power | 1.6KW |

| Effective Trip | 750*400*80mm |

| Worktable Size | 740*430mm |

|

|

Full Automatic Rubber Making Machine 220V For Pvc Rubber Patch Logo Making Images |